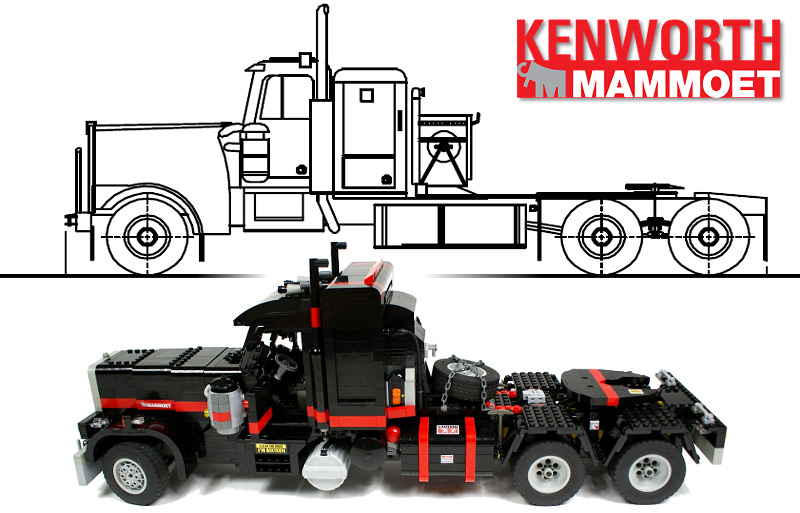

Model of the Kenworth W900 in a version customized by the Mammoet company. Features full pendular suspension, functional steering wheel, R4 piston engine, openable bonnet, sleeper’s roof and doors, remotely controlled front and rear lights, automated reverse lights and trafficators, remotely locked catch and custom stickers. My first construction powered by the Lego 8878 rechargeable battery.

Datasheet:

Completion date: 29/06/2009

Power: electric (Power Functions)

Dimensions: truck – length 75 studs / width 19 studs / height 26 studs, trailer - length 111 studs / width 18 studs / height 12 studs

Weight: truck – 2.66 kg, trailer – 0.709 kg

Suspension: truck – full pendular, trailer – none

Motors: 2 x 71427, 1 x PF Medium, 2 x PF XL

Kenworth W900 is one of the most iconic US-type trucks, and the Mammoet is one of the most impressive companies ever, handling stuff like transportation of bridges or houses on a daily basis. Moreover, it is a Dutch company, just like the Lego, and it uses almost entirely black livery for its vehicles which is very appealing for me. Finally, the Mammoet fleet, which consists of some of the world’s biggest and most powerful vehicles in their class, contains a number of customized vehicles, which makes them even more interesting.

There is one obvious point of reference for this model, that is my Tow Truck, completed almost a year earlier. I have assumed that it would be difficult to exceed its level of technical complexity, and if I tried to, it would most likely result in a vehicle of even bigger size and similiar look. That is why Kenworth was meant to be simplier and built with more focus on its aesthetic side.

First thing about the aesthetics are somewhat missed proportions – although according to Mammoet’s blueprints only the bonnet is 2 studs too long, and the rest of dimensions is more or less correct. Nevertheless, the truck looks long and narrow. I have recreated Mammoet’s livery on the body, but not on the bumpers, preferring to keep them free from paint job. Instead, they were fitted with small warning badges, and on the front bumper has a set of guards that Mammoet company uses in trucks intended to push some loads. There are no warning lights, either. I’ve put a lot of work into the bonnet, which can be opened up together with the front mudguards, which is a realistic solution unlike the one used in my earlier Tow Truck. The sleeper was made taller to fit the mechanics in, the catch was increased in size to achieve more accurate shape, and rear mudguards were added.

The model was designed for use with a standard Power Functions battery box, and only in the last stage of building it received the Lego 8878 rechargeable battery instead. The battery decreased sleeper’s height and truck’s weight (by considerable 160 grams) while not impacting the performance in any apparent way.

The suspension system consisted of three simple pendular modules, with axles #2 and #3 using my 3-studs wide differential bracings, each stabilized by four hardest 6.5L shock absorbers available to handle the truck’s weight and load. The front axle had no shock absorbers at all, because too much place was taken by the bonnet and front mudguards. Since the entire suspension is pendular, the truck is susceptible to a transverse tilt resulting from the driveshaft’s load, but it is greatly limited by the hard shock absorbers.

The model is driven by two PF XL motors facing each other and connected by four bevel gears. I have tested this setup before, and I liked how simple and effective it was. Additionally, the use of two motors facing each other substantially reduces the strain on the drivetrain. When I tested it with a single motor, it had a tendency to pull the driveshaft down or up if it was not reinforced properly. With two motors, the driveshaft remains in place because while one motor pulls it up, the other pulls it down. One of the four bevel gears is an idler gear, used only to keep the other three gears in place. It can be easily noticed that the motors would look better if they were located along the body – they would then look just like the fuel tanks. It’s a nice solution, but it makes the vehicle’s frame and transmission much more complex, and so I gave it up. I have to mention that the truck turns surprisingly smoothly, most likely thanks to the long span between the steered axle and the driven axles. And it feels very pleasant and realistic to drive it with the speed control-enabled 8879 handset.

It may come as a surprise, but there is no gearbox whatsoever. I’ve done a lot of tests with a linear 3-speed manual gearbox, which seemed most adequate due to it size and robustness, but it proved somewhat loose and the model performed much better with no gearbox. I intended to use the speed control feature anyway, so the gearbox was eventually removed.

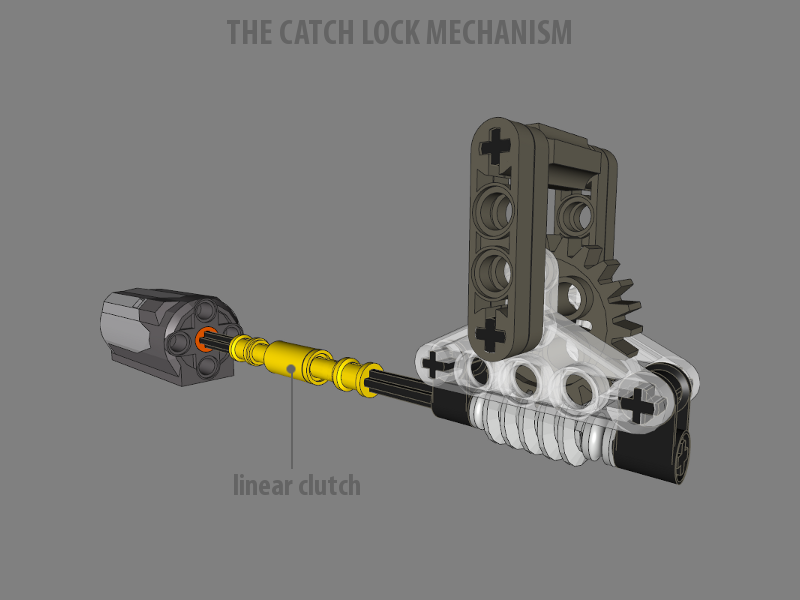

The catch lock mechanism is very simple and compact. It uses a worm gear to hold the trailer in place, and a linear clutch to avoid damage. It was located just above the last axle, which is why I’ve used a custom casing (the standard Lego casing wouldn’t fit in), and it was driven by a motor located in the chassis, directly in front of the second axle.

Slightly in front of the second axle, there is also the steering system’s power output, intended to be connected to the trailer’s own steering system to couple it with the truck’s steering. I have tested a trailer with such a system, but I eventually faced the choice whether to make the trailer with steered axles or to make the trailer which is strong and looks realistic. I have chosen the latter.

Between the fuel tanks, there is a reverse lights activator in the chassis. It consists of a single PF switch whose movement is limited to a neutral and one extreme position , and which is connected to the driveshaft through a clutch. The reverse lights are powered from the same output as the drive engine, thanks to which they go out as the truck stops.

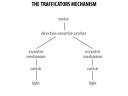

The doors of the cab can be fully opened after removal of their side bars. Inside the cab, there is a functional steering wheel and a simple cockpit. There are no seats, because the respective space is occupied by the trafficators mechanism. I will now explain how it works. Imagine a PF light powered through a PF switch – it blinks as the switch’s position changes. Such a motion can be easily motorized by means of an eccentric mechanism – that kind of solution was already used in the forementioned Tow Truck, and can be well seen in my Snowgroomer. Now, imagine a ratchet that is sensitive to the direction of rotation – it has been used in my direction sensitive gearbox. We can attach the motor to the ratchet, and then prepare two separate eccentric mechanisms with two separate PF switches and two separate set of lights (of any size – in fact, I would make the rear trafficators work too if I had 9 lights instead of just 7). It will result in a mechanism when only one eccentric mechanism is driven at a time, and it changes as the direction of rotation of the steering motor changes. Thus, it is perfectly possible to use the steering motor for it, as it can easily control one more mechanism, and I have used a separate motor here only to be able to locate the trafficators mechanism independently of the steering motor’s location. The trafficators’ lights are powered from the same output as the steering motor, so they go out when it stops working, regardless of the wheels’ position.

One drawback of this solution is that the eccentric mechanism remains in whatever position it was when the ratched moved to the other one. It means that there is a high risk of having all trafficators come up at the same time, because the ones that should be off will have the PF switch stopped in ‘on’ position. It can be prevented with rubber bands that pull the eccentric mechanisms to a specific position once they no longer mesh with the ratchet, but I did not use such means of prevention because of the available space limitations. Please note that the truck already houses approximately 5 meters of electric wire.

Under the bonnet, there is a R4 piston engine with moving pistons and rotating front fan. It is small because of the limited space under the bonnet which results from its specific construction. As you can see on the photo below, there is an interesting area near the front axle where the model’s smooth external surface ends and a Technic structure can be seen beneath it.

Finally, the trailer. I wanted it to wear a different colour scheme. Trailers of this type usually have red and white warning stripes on the edges of main platform. I didn’t have the needed number of red and white parts, and I disliked the look of these colours combined so I replaced them with two shades of grey. The trailer has no steering system nor suspension of any kind, and it is attached to the truck in a fairly simply way. I have to admit that the truck took a terrible amount of work to build and I really didn’t like the idea of even more work with the trailer, especially since it was difficult to show or film together with the truck due to its length. Therefore the trailer is an addition to the truck rather than a proper model.

Overall, the model enjoyed a fairly good reception, despite many people pointing the proportions issue out. The trafficators feature was widely acclaimed, and there was even a number of people who were very critical about the proportions and accuracy of the truck, but still regarded it as an impressive model. Few people declared that the focus on the truck’s aesthetic aspect was much greater than expected of me, and that its functionality was degraded because of this.

Photos:

Video:

Click here to view the embedded video.